Quality Control

Great Precision. Unmatched Excellence.

Like other industries, quality control is an indispensable component of granite manufacturing. Since granite is prevalently used in both residential and commercial construction, the chosen granite slab must be perfect in terms of size, color, and finish. This is where quality control plays a role by leaving no space for flaws in the final product.

At Regatta Granites India, we employ proven quality control methods to manufacture flawless granite products for our buyers for any kind of project they are working on. We understand that being a natural stone, granite may contain natural color variations. This is why we pay careful attention to the process from the beginning. This helps us lay down a solid foundation for further processing.

With nearly 30 years of industry expertise, we take pride in manufacturing and deliver granite products that consistently surpass global standards for strength, appearance, surface finish, and longevity.

Enduring quality, delivery trust

Our eye for detail helps us ensure world-class product quality

Why quality control matters in the granite industry

Granite is a premium natural stone, largely used in both residential and commercial applications—where aesthetics, performance, and longevity holds immense value. Any kind of compromise in quality can lead to:

- Structural cracks or surface wear

- Improper colors across slabs or tiles

- Poor quality finish or polish degrading overall aesthetic appeal

- Lesser customer satisfaction and trust

Quality control in granite manufacturing is not a choice but a necessity which ensures.

Dimensional accuracy

- Consistent polishing & calibration

- Defect-free surfaces

- Uniform color and pattern across different lots

- Enduring resistance to weathering, staining, and load stress

Our Multi-Level Quality Assurance Process

At Regatta Granites India, we’ve put in place a rigorous quality inspection system at every critical stage. Our in-house team of quality control professionals inspects every slab and tile, using high-end tools and global standards to keep the quality in check.

Raw Material Inspection

- Only premium-grade blocks are chosen from top granite quarries

- Visual and physical inspection for defects, cracks, and inconsistency

- Color tone, mineral & grain composition inspected before processing.

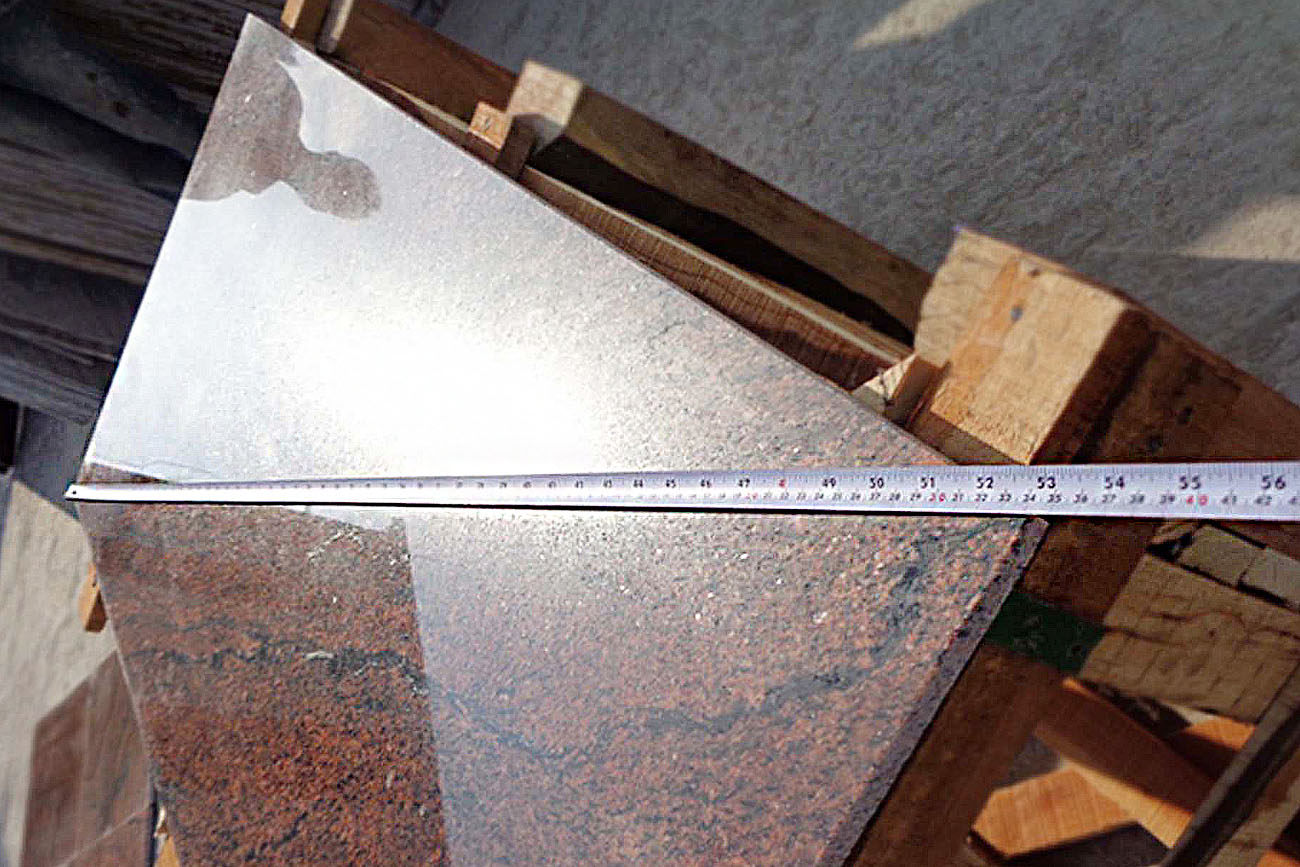

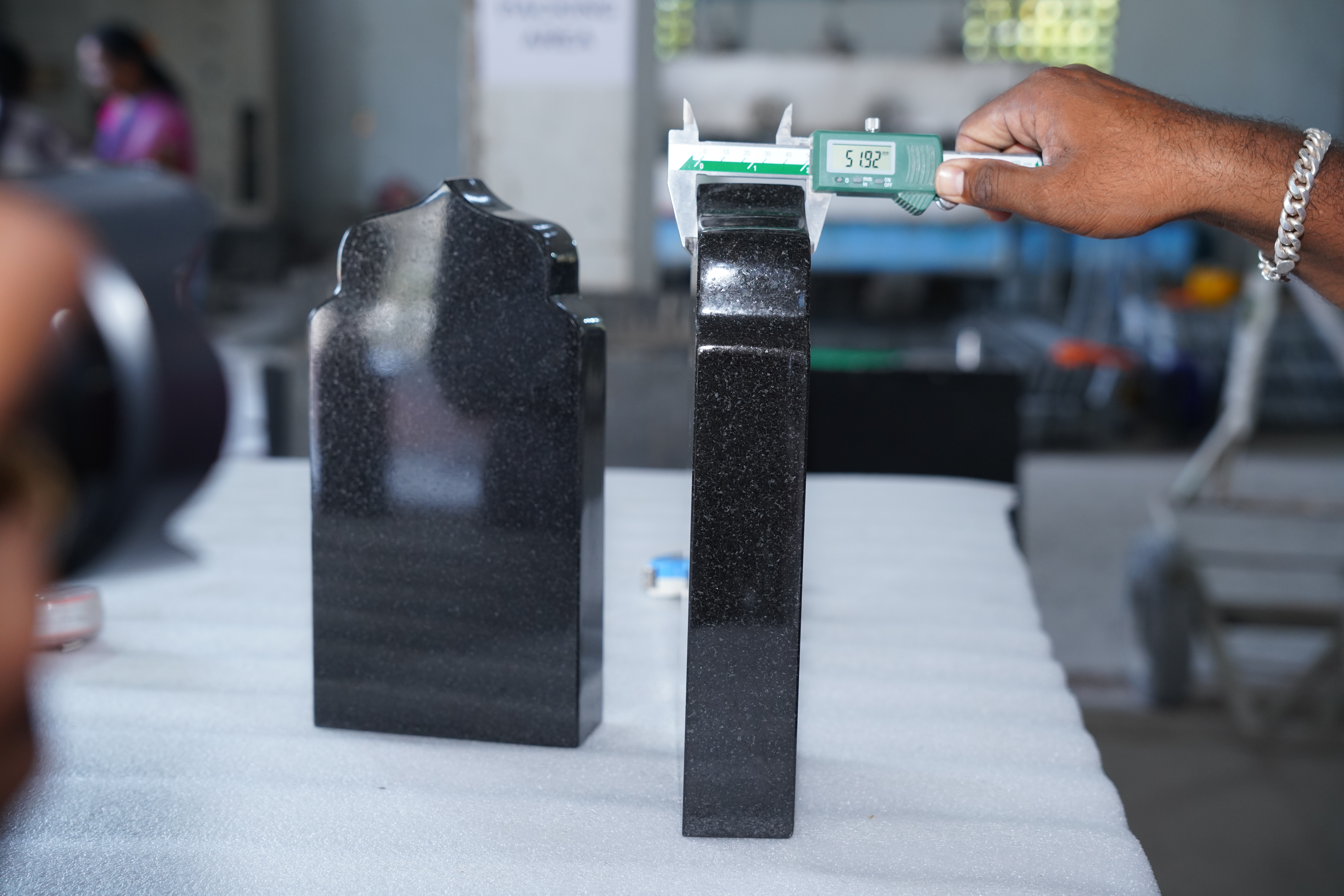

2.Cutting & Sizing Precision

- Gangsaw and multi-blade machines calibrated regularly

- Tolerances sternly preserved as per international standards

- Each slab is thoroughly checked for length, width, and thickness accuracy.

3.Surface Finishes

- Automated polishing lines deliver consistent shine

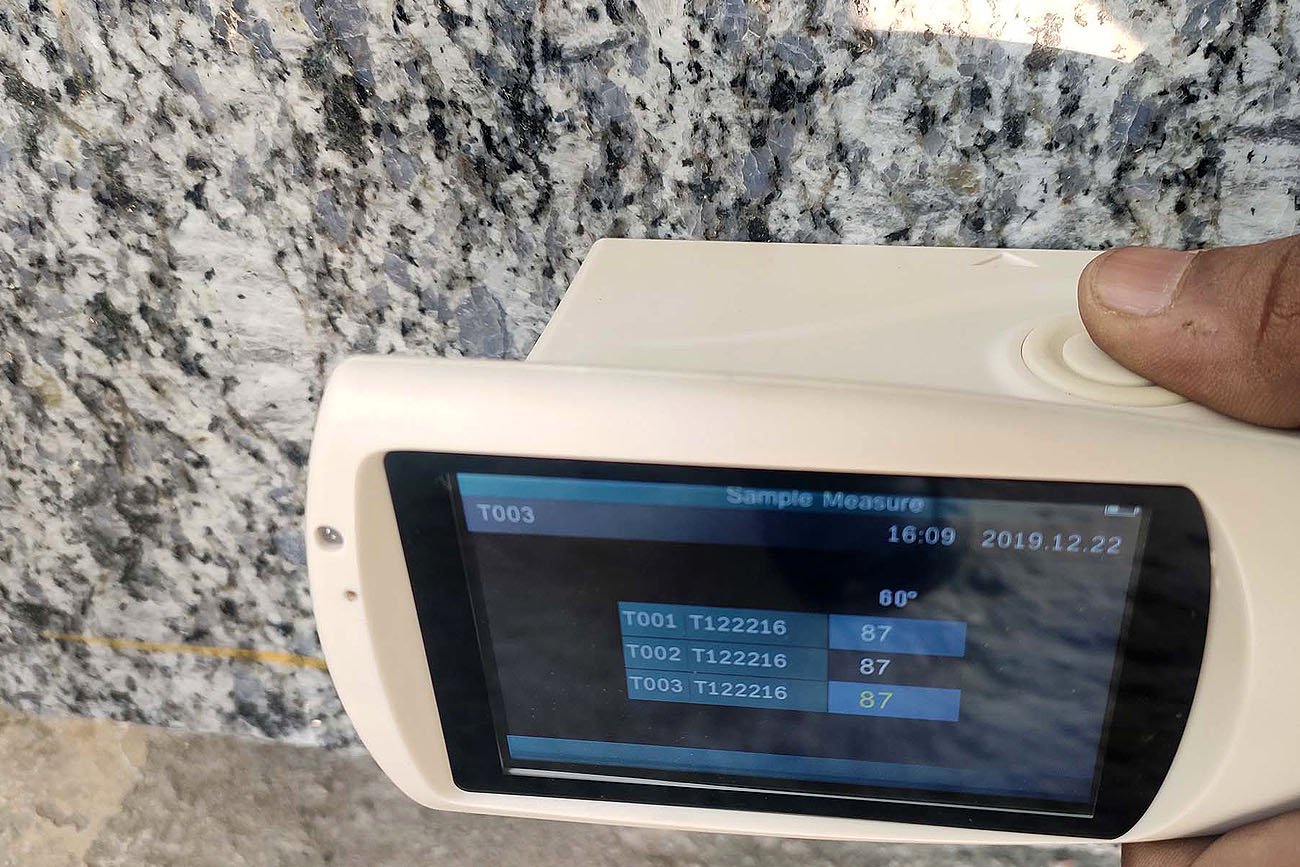

- Inspection for polish clarity, scratch resistance, and gloss level

- Custom finishes (leather, flamed, honed, etc.) are checked for integrity

4. Final Inspection Before Packing

- Visual inspection under natural and artificial lighting

- Checked for warping, edge finish, chips, or cracks

5.Packaging Quality

- Water-resistant and sturdier wooden crates

- Fumigation and moisture protection ensured for long transit

Different types of quality inspection reports provided by Regatta Granites India

1. Material Inspection Report

- Details include appearance inspection for color consistency, pattern check, chips, cracks, or pinholes.

- Determines the exact grade of the granite such as standard, commercial, standard, and premium

- Highlights natural variations or tolerable imperfections.

3. Dimensional Accuracy Report

- Details related to thickness, length, and width.

- Tolerance range usually within ±1 mm for thickness and ±2 mm for length/width.

- Squareness and edge measurements.

4. Physical Property Test Reports

- Water Absorption: Checks porosity; which must be < 0.5% for high-quality granite.

- Density/Specific Gravity: The preferred value is around 2.63 – 2.75 g/cm³.

- Compressive Strength: Measures load-handling capacity.

5. Surface Finish Quality Report

- Assesses the gloss level (measured in gloss units – GU) for polished granite.

- Inspects finish type: polished, flamed, honed, leathered, bush-hammered, etc.

- Measures surface smoothness and uniformity.

6. Packing & Quantity Verification Report

- Ensures the delivery of required quantity.

- Checks the use of appropriate wooden crates/foam sheets for damage prevention during transit

- Highlights pallet weights and labeling details.

7. Photographic Inspection Report

- High-resolution pictures of processed slabs/tiles packed for dispatch.

- Depicts surface, edges, and side angles.

8. Third-Party Quality Inspection Report (Optional but Preferred)

- Done by agencies like SGS, TUV SUD, or Bureau Veritas.

- Generally preferred for high-volume or high-end orders.

9. Color Consistency & Lot Uniformity Report

- Authorizes slabs/tiles from the same batch with minimal variation.

- Important for large-scale construction projects to avert incompatible installations.

Why clients trust Regatta for granite imports

- Exporting to 60+ countries across 5 continents

- State-of-the-art manufacturing with advanced machinery

- Professional and committed in-house quality control experts

- Association with several clients globally

- Proper order documentation

Your reliable partner in quality granite delivery

Whether it’s a large-quantity order for commercial construction or a custom requirement for a residential project, Regatta Granites India ensures flawless process execution, well supported by certified quality assurance and a client-centric work approach. Consult our experts today to discuss your project.